Joint Savers

Joint Savers stop your concrete slabs from moving when you drive over them.

Stabilize Your Concrete with Joint Savers

Prevent concrete slab movement and ensure smooth transitions with Joint Savers. ABC Concrete Cutting Company introduces the Joint-Saver, designed to maintain the integrity of your concrete joints and eliminate the inconvenience of loose or damaged slabs.

Revitalize Your Concrete Joints

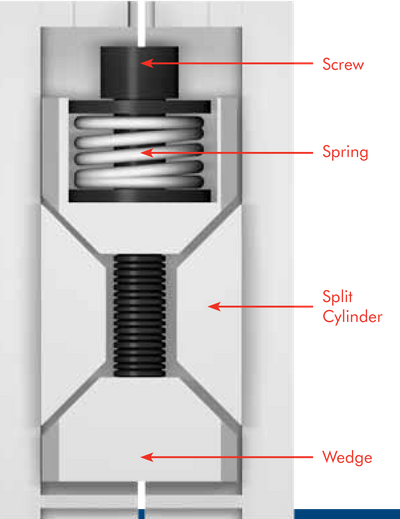

Dealing with uneven, shifting, or damaged concrete joints can disrupt operations, damage equipment, and even pose safety risks. The Joint-Saver offers a swift and cost-efficient solution to these issues. With three available sizes—SD5, SD6, and SD7—Joint-Savers cater to a wide array of floor thicknesses, ensuring a permanent restoration of seamless load transfer across all joints and cracks.

Engineered to perform even in cold conditions and withstand significant temperature variations, the Joint-Saver promises to restore your floor's original functionality, enhancing efficiency and profitability by rectifying floor issues.

Advantages of Implementing Joint Savers:

Reestablish effective load distribution across joints.

Quick installation minimizes operational downtime.

Boosts productivity by reducing vehicle wear and maintenance needs.

Significantly reduces accident and injury risks, safeguarding against product damage.

Enhances overall operational efficiency and profitability by minimizing maintenance and management expenses.

Our team will manage the entire installation process, from initial site assessment to coordinating with the manufacturer for optimal placement recommendations. Following your approval, we will procure the necessary Joint-Savers and complete the installation.

Should future adjustments be necessary due to slab movement, the Joint-Saver devices are designed for easy recalibration, ensuring long-term stability and performance.

"We go through about 20 load wheels per month just due to the floor."

"Add in two bearings per load wheel and possibly switches, springs, bump stops and other related parts that are affected by the constant hard jolting of the lift vehicle," says H. Lee Williams, Pep Boys NY/DC Facilities Manager, Maintenance

Department. "Plus you have to factor in the 1/2 hour of labor that it takes to repair each vehicle and the lost productivity of the operator while the lift is down."